Autoflame burner controllers save energy at London’s Leadenhall Building and for the NHS

ETL listed Autoflame Mini Mk8 MM micro-modulating controllers deliver substantial energy savings in two very different applications

Autoflame was founded in 1968 and specialises in precise, intelligent combustion management systems.

Its Retrofit Burner Control Systems are listed on the ETL and are among the most energy efficient products in the market in their class.

There are over 20,000 Autoflame controllers currently in operation. The company has a global partner network of 130 exclusive, highly trained Technology Centres that install, support and maintain its systems on a local level.

Autoflame provides combustion management solutions for commercial and industrial applications. These include an NHS hospital in the west of England, and the Leadenhall Building, a 225-foot skyscraper in the heart of the City of London’s financial district.

The buildings have very different uses. The NHS hospital is a large, public healthcare hub, whilst the Leadenhall Building is one of London’s best-known landmarks and is home to businesses providing financial services, as well as shops and restaurants.

The common feature between both buildings are the ETL listed Retrofit Burner Control Systems by Autoflame, installed to increase system reliability, reduce energy consumption, as well as lower operating costs and emissions.

The challenge: Low efficiency and reliability of existing systems drove high fuel bills and operational challenges

Both buildings required an energy efficiency upgrade to increase reliability, reduce fuel costs and emissions, and facilitate accurate emissions measurement and reporting.

The existing boiler at the NHS hospital was 20 years old, had a low turndown ratio and higher than average excess air readings (compared to industry best practice). The low turndown ratio led to frequent boiler cycling, resulting in excessive purging and boiler cooling. This led to a decreased energy output per kWh of energy, and increased wear and tear on the boiler which caused a rise in maintenance costs.

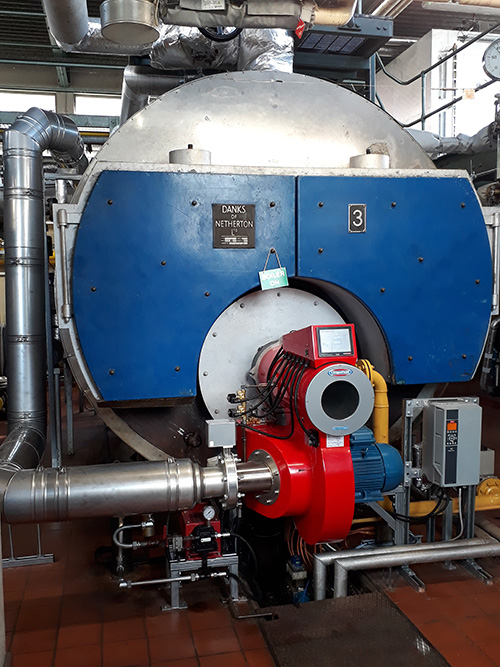

The existing boiler at the NHS hospital

Autoflame identified the list of challenges at the NHS hospital:

- To increase efficiency of the boiler plant

- A reduction in fuel consumption, costs, and associated CO2 emissions

- A reduction in O2 levels

- A reduction of Nitrogen Oxides (NOx) levels to meet Medium Combustion Plant Directive (MCDP) requirements

- Monitoring and logging emissions

At the Leadenhall Building, managed by BGIS, the boiler plant room is uniquely situated on the 47th floor with no defined roof. It was suffering from seasonal variations in conditions due to its highly elevated position and open-air nature.

The existing burners were unreliable in the open-air boiler room and susceptible to unscheduled downtime. The customer also wanted to increase efficiency and improve the environmental impact of the building by reducing the amount of harmful greenhouse gas emissions released into the atmosphere.

The Leadenhall Building boiler before the refit

Autoflame identified the challenges at the Leadenhall Building:

- Increasing the reliability of the plant room to cope with seasonal variations

- Increasing the performance of the plant, reducing harmful emissions including carbon dioxide (CO2), NOx and sulphur dioxide

- Enabling tracking and logging of emissions for reporting purposes, to contribute to environmental goals at the building

The solution: Upgrading to Autoflame Retrofit Burner Control Systems

Autoflame installed new ETL listed energy efficient systems in both buildings, which delivered instant energy and emissions savings.

At the NHS hospital, Autoflame installed controllers - a pod-mounted, Autoflame Mini Mk8 MM listed on the ETL in the Retrofit Burner Control Systems sub-technology, as well as a multi-award winning Autoflame Mk8 EGA EVO, which measures up to six greenhouse gases and enables accurate emissions reporting. They were fitted to ensure high turndown and precise fuel/air ratio control throughout the firing range.

The controllers were attached to a new Limpsfield LCN030 burner with flue gas recirculation (FGR) to reduce NOx levels.

The NHS hospital boiler after the refit, including pod-mounted Mk8 MM controller

At the Leadenhall Building, Autoflame first conducted an energy audit, taking gas samples from the flue and analysing them with Autoflame's unique Emissions Calculator software – delivering an accurate savings and ROI estimate.

The burner was fitted with the ETL-listed pod-mounted Autoflame Mini Mk8 MM, targeted to reduce CO2 emissions by 10% and fuel use by 5-7%. An Autoflame Mk8 EGA EVO was installed to deliver maximum energy efficiency, and for emissions measurement and reporting.

A custom-made, high-efficiency Limpsfield burner was installed due to its ability to withstand extreme environments to deliver reliability in the highly exposed, open-air plant room. The control system is fitted to the burner.

The Leadenhall Building boiler after the refit

Pod-mounted Mk8 MM controller

The result: Reductions in both energy and costs

The NHS hospital saw a projected efficiency improvement (gross) of 0.84%, as well as an improved turndown and reduced boiler cycling. This yielded a 7.03% saving in fuel costs, or £9,605 per year.

Emissions were reduced by 15.14%, with a 59.26% reduction in NOx emissions, exceeding MCPD requirements.

At the Leadenhall Building, the building management company confirms that £60,000 per year is now saved in energy since the installation, with a return on investment (ROI) of two years from installation. There has been a reduction in CO2 emissions equivalent to 180 tonnes per annum.

The management company says the reliability of the plant has been improved, with a significant reduction in downtime.

The Leadenhall project is now used as a blueprint for other BGIS sites looking to reduce emissions and fuel bills, winning the company’s 2023 BGIS Global Supplier Innovation Award.

Billy Huggett, Director, Autoflame Service & Support said:

Autoflame Service & Support has supported BGIS with boiler room maintenance for many years, but the upgrade in The Leadenhall Building vastly exceeded BGIS’s expectations, reaching ROI in under two years, and delivering energy savings of £60,000 and CO2 savings of 180 tonnes per annum. We were honoured to receive the 2023 BGIS Global Supplier Innovation Award and are now a preferred supplier.

For more details on Autoflame, head to the company’s website.

Browse Boiler Retrofit Equipment on the ETL

If you’re a purchaser looking to browse Boiler Retrofit Equipment on the ETL, you can find the Autoflame Mini Mk8 MM under the Retrofit Burner Control Systems sub-technology. You can also choose from many more products using the technology filter and choose multiple products to compare.

If you’re a manufacturer of energy efficient technology, you can apply to list your products on the ETL - just head to our Manufacturers page.

Make sure to also check out our YouTube channel, for video explainers on energy efficiency, as well as insights from industry experts.

We are always looking to feature stories on energy efficiency, decarbonisation and Net Zero. Check out our selection of case studies, including HeatingSave and Quintex.

If you'd like us to include your company or customers’ energy efficiency story, please contact us: media@etl.energysecurity.gov.uk.