1.1 Scope

Wastewater heat recovery systems cover heat recovery technology that is specifically designed to use residual heat from drained wastewater via an instantaneous heat exchange to pre-heat incoming mains water. These systems save energy by reducing the energy consumption of hot water heating equipment, such as boilers.

They can be used to recover waste heat from wastewater streams where there is a simultaneous demand for hot water, such as showers, dishwashers, industrial processes etc.

1.2 Definitions

Wastewater heat recovery systems normally consist of a long copper pipe, where the warm water runs alongside the colder mains water to allow the heat exchange to occur. These devices typically have no electrical components, pumps or controllers, requiring very little maintenance.

Wastewater heat recovery systems are available in a range of different designs and efficiencies, where product suitability is determined by the specific requirements of the application. The Energy Technology List (ETL) Scheme aims to encourage heat recovery from wastewater streams and the purchase of higher efficiency products suitable for a given application.

1.2.1 Sub-categories

The ETL Scheme covers three categories of wastewater heat recovery systems:

- Standalone horizontal systems: consisting of a single instantaneous heat exchanger installed horizontally underneath the wastewater stream.

- Standalone vertical systems: consisting of a single instantaneous heat exchanger installed vertically, connected to one or more wastewater streams.

- Plant room systems: consisting of a single instantaneous heat exchanger, normally located in a plant room connected to multiple wastewater streams.

To be eligible for inclusion on the ETL, products shall meet minimum eligibility criteria as set out below.

1.3 Requirements

1.3.1 Eligibility requirements

To be eligible, wastewater heat recovery systems shall:

- Be specifically designed to recover heat from shower and bath drains, by means of an instantaneous heat exchanger for simultaneous hot water pre-heating.

- For standalone systems, the pipework run between the unit from which waste heat is being recovered (e.g. shower tray) and the heat exchanger – shall be designed to be no greater than 3 metres, and this shall be stated in the installation requirements.

- Maintain conditions that comply with ACOP L8: 2013 “Approved Code of Practice and guidance – Legionnaire’s disease. The control of legionella bacteria in water systems”.

- Comply with the requirements of the Water Supply (Water Fittings) Regulations 1999, the Water Byelaws 2000 Scotland and the Water Regulations in Northern Ireland (for example, by inclusion in the Water Regulations Advisory Scheme’s Water Fittings and Materials Directory or by manufacturer/supplier declaration).

- Be designed to prevent backflow through the use of twin wall construction and venting – this can be demonstrated by compliance with BS EN 1717:2000 “Protection against pollution of potable water in water installations and general requirements of devices to prevent pollution by backflow”.

- For wastewater heat recovery systems made from copper, these shall be designed and manufactured in compliance with one of the following or other equivalent international standards:

- BS EN 1057:2006+A1:2010 “Copper and copper alloys. Seamless, round copper tubes for water and gas in sanitary and heating applications (for copper tubes and fittings)”;

- ASTM B88 - 16 “Standard Specification for Seamless Copper Water Tube” and ASTM B306 - 13 “Standard Specification for Copper Drainage Tube (DWV)”.

1.3.2 Performance requirements

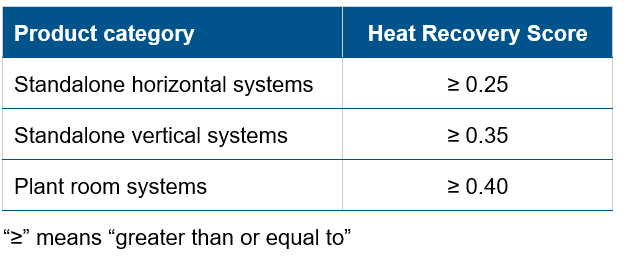

Wastewater heat recovery products shall have a Heat Recovery Score greater than or equal to the figures shown in Table 1.1 below.

Table 1.1 Performance thresholds for wastewater heat recovery systems

1.4 Measurement and calculations

1.4.1 Measurement standards

The following guidance and standards shall be used to determine product performance:

- NTA 8800:2019-06 nl “Energieprestatie van gebouwen – Bepalingsmethode” (Energy performance of buildings - Determination method)

- Tests and performance measurements carried out in accordance with NEN 7120:2011/C2:2011 nl “Energieprestatie van gebouwen – Bepalingsmethode” (Energy performance of buildings - Determination method) will be accepted in place of NTA 880:2019-06 nl. - CSTB Protocole RECADO 2015

- Tests and performance measurements carried out in accordance with CSTB Protocole RECADO 2012 will be accepted in place of RECADO 2015. - CSA B55. 1-15 “Test method for measuring efficiency and pressure loss of drain water heat recovery units.”

- for standalone vertical and plant room systems only - IAPMO IGC 347-2017 “Test method for measuring the performance of drain water heat recovery units.”

- for standalone vertical and plant room systems only - The Government’s Standard Assessment Procedure for Energy Rating of Dwellings, 2012 edition (SAP 2012)

1.4.2 Performance metrics

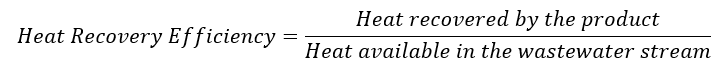

The Heat Recovery Score is a performance parameter based on the heat recovery efficiency and the utilisation factor of the product, calculated using the equation below:

![]()

Where:

- The Heat Recovery Efficiency in % is the heat recovered by the wastewater heat recovery system as a proportion of the heat available in the wastewater stream. It shall be calculated in accordance with heat transfer principles, following the prescribed method in the test standard being used (from Section 1.4.3). In general, the heat recovery efficiency is described by:

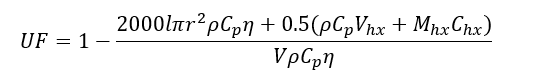

- The Utilisation Factor (UF) is a factor between 0 and 1, which accounts for energy losses not included in the laboratory data but are likely to occur in an installation. These losses include energy lost from the water in the heat exchanger and from the water in the connecting pipes.

The product’s UF shall be calculated using the following equation in accordance with the SAP 2012 guidance for a balanced system where the incoming cold and wastewater stream flow rates are equal:

Where:

l is the installed pipe run length (preheated water output from heat exchanger to unit from which waste heat is being recovered). 3 metres is taken as typical for standalone systems. For standalone horizontal systems fitted directly into the unit from which waste heat is being recovered e.g. fitted in a shower tray, an installed pipe run length of 1.5 metres should be used.

r is the inside radius of the connecting pre-heated water outlet pipe from the wastewater heat exchanger in metres

ρ is the density of water (use 1 kg/litre)

Cp is the specific heat capacity of water (use 4.19 kJ/kg.K)

η is the heat recovery efficiency, as determined above

Vhx is the volume of water in the heat exchanger in litres

Mhx is the mass of the dry wastewater heat exchanger in kg

Chx is the specific heat capacity of the heat exchanger in kJ/kg.K

V is the volume of water in the unit from which waste heat is being recovered in litres. This should be assumed to be 66 litres for the UF calculation for standalone horizontal and vertical systems.

The 2000 multiplication factor consists of two factors:

- ×1000 is to convert the pipe volume from m3 to litres

- ×2 assumes the wasted drainage water volume is the same as the wasted pre-heated outlet water volume. For horizontal systems fitted directly into the unit e.g. fitted in a shower tray, only the wasted water in the pre-heated heat exchanger outlet pipe needs to be accounted for. Halving the installed pipe run length to 1.5 metres for these product types, as stated above, is a simple approximation to account for this.

Confirmation of the Utilisation Factor can be provided by listing of the product on the Product Characteristics Database on the Building Energy Performance Assessment support website.[1] Otherwise all parameters used in calculating the utilisation factor should be presented in the test report.

1.4.3 Test requirements

Testing and performance measurement shall be carried out in accordance with any of the following test standards:

- NTA 8800:2019-06 nl “Energieprestatie van gebouwen – Bepalingsmethode” (Energy performance of buildings - Determination method)

- CSTB Protocole RECADO 2015

- CSA B55. 1-15 “Test method for measuring efficiency and pressure loss of drain water heat recovery units.”

- IAPMO IGC 347-2017 “Test method for measuring the performance of drain water heat recovery units.”

Performance data shall be based on testing carried out for conditions that fall within the limits below, adhering to the tolerances prescribed in the test standard:

- an average flow rate volume of between 8 and 11 litres per minute

- a room temperature of 20°C

- an incoming mains cold water temperature of between 10 and 13°C

- a drain water temperature of between 37 and 40°C

The specific test conditions under which the performance is measured shall be presented in the test report. Where performance has been measured at multiple test conditions, these shall also be presented in the test report.

The test apparatus shall be set up such that the pre-heated water from the wastewater heat recovery system flows into both the cold water feed for the water heater and into the cold water feed for the unit from which wastewater heat is being recovered. For example, where heat is being recovered from a shower supplied with hot water from a boiler, the pre-heated water shall flow into the boiler cold water feed and into the shower mixer cold water feed.

1.4.4 Rounding

For the avoidance of doubt the Heat Recovery Score should be presented to 2 decimal places. As an example, a standalone vertical waste water heat recovery system with a Heat Recovery Score of 0.34 would be deemed to not meet the performance requirements.

1.5 Verification for ETL Listing

Any of the following testing routes may be used to demonstrate the conformity of products against the requirements:

- In-house testing – Self-tested and verified or cross-checked by an independent body

- Witnessed testing

- Independent testing

Further information regarding the first three routes can be found in the ETL Testing Framework.

1.6 Conformity testing

Products listed on the ETL may be subject to the scheme’s conformity testing programme in order to ensure listed models continue to meet the ETL requirements.

1.7 Review

1.7.1 Indicative review date

This specification will be reviewed during the 2023/24 ETL review cycle.

1.7.2 Illustrative future direction of the requirements

With the recent introduction of wastewater heat recovery systems to Building Regulations Part L calculation software for non-domestic buildings, commercial applications for these systems will continue to evolve in the coming years. Future eligibility and performance requirements will be reviewed to account for this.

[1] https://www.ncm-pcdb.org.uk/sap/pcdbsearch.jsp?type=353&pid=33